Product Quality Check

At ZanattaVetro, we ensure that every glass product meets the highest standards through a rigorous quality check process. Our commitment to excellence is reflected in our comprehensive approach to verifying the quality of finished products. Each finished product undergoes a thorough inspection to ensure it meets all specified criteria. We assess visual and structural aspects to confirm that the glass meets our exacting standards.

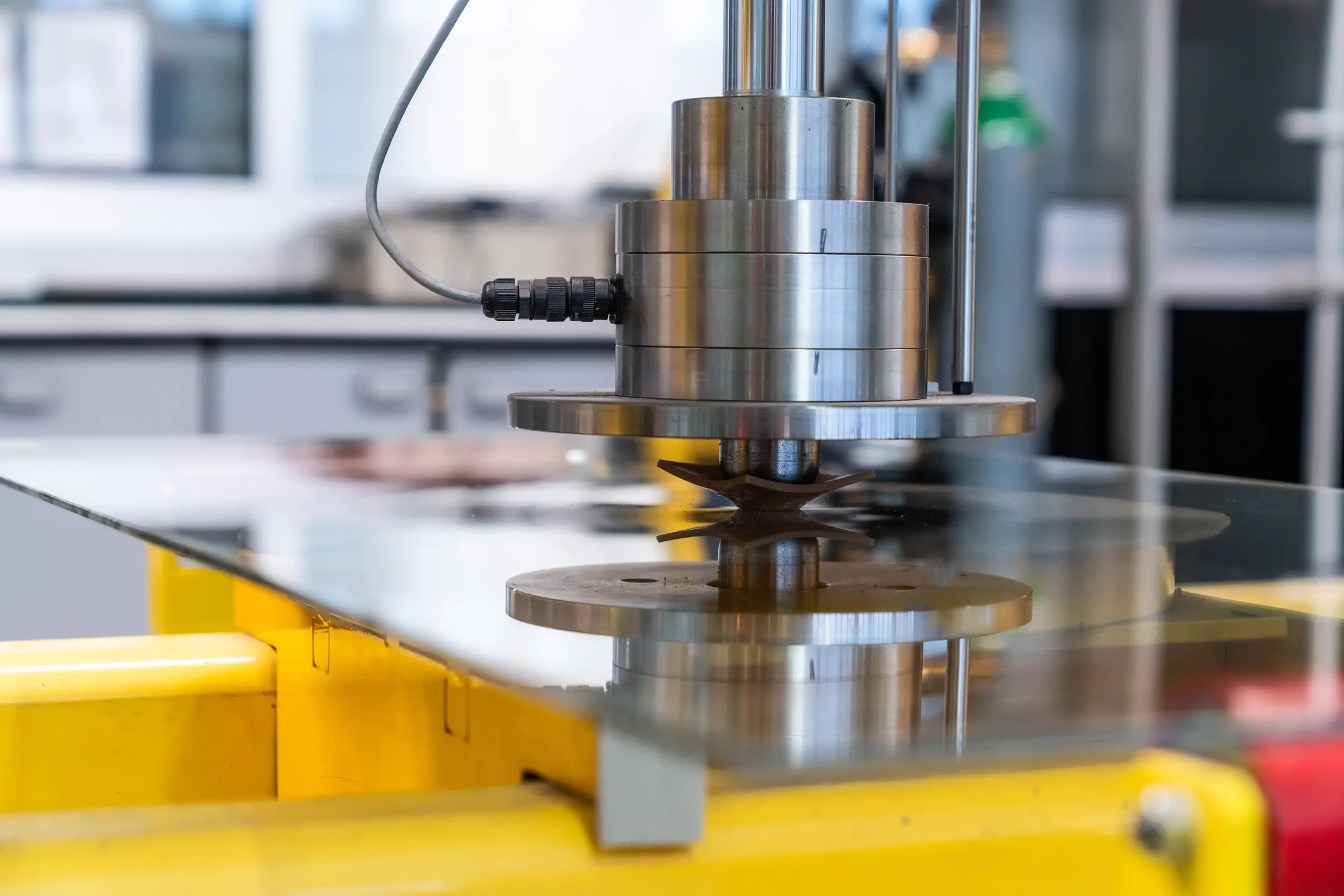

Daily Tempered Glass Breakage Test

To ensure the reliability and safety of our tempered glass, we perform daily breakage tests. This process allows us to recalibrate the furnace as needed to maintain optimal performance and safety standards. Our tempered glass adheres to the EN 12150 standard, which requires a flexural strength of at least 120 N/mm² (newton per millimeter squared) for standard float glass. We go beyond this requirement, testing at 200 N/mm² to ensure superior strength and durability.After breakage, the glass must fragment into relatively harmless small pieces. The standard specifies that at least 40 fragments must be collected in a 50×50 mm area at the center of the glass sheet for thicknesses up to 4 mm. At ZanattaVetro, we achieve 60 fragments, exceeding the standard for enhanced safety.

Laminated Glass Breakage Test

For each production batch, we conduct breakage tests on laminated glass to ensure its strength and safety. This rigorous testing process guarantees that every batch meets our high standards for durability and quality.

Insulated Glass Scanner

We use advanced scanning technology to inspect insulated glass units. This scanner checks for any imperfections and ensures that each unit meets our stringent quality requirements.